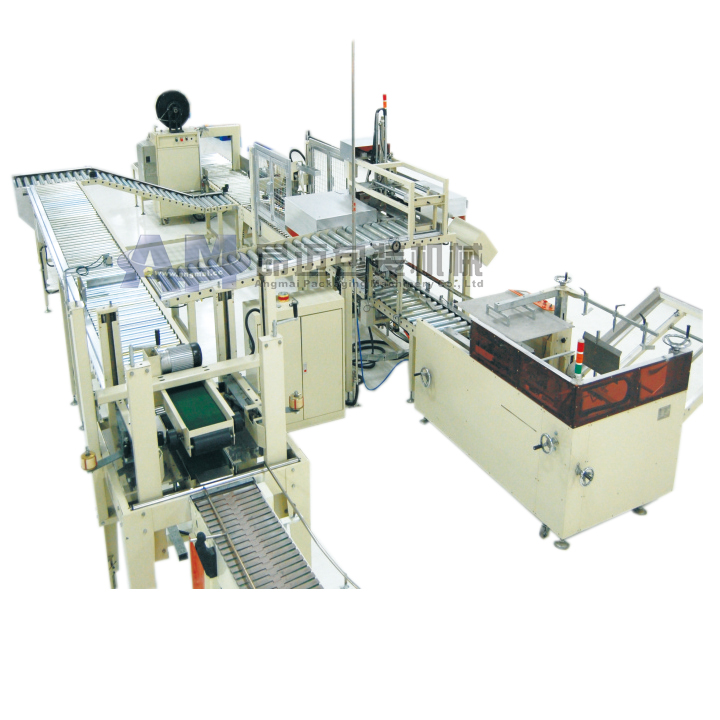

Automatic unpacking, packing, box sealing and strapping line in food industry

One,preparation

1.mechanical fastening parts connection is firm, the instrument and meter work is normal.

2.gas pressure 50 ~ 110mbar, air pressure 0.5 ~ 0.55MPa.

3.conveyor and photoelectric switch without foreign body blocking.

Two,operation instructions

1.open air and compressed air valve, close the control power supply.

2.press the reset button on the control panel.

3.start automatic packaging mode.

4.roller machine, the site operation button yellow indicator light. Electric forklift fork from the unit, take down the craft tray, put down the unit to withdraw from the forklift, press the operation button 3 seconds after entering the automatic packaging operation.

5.Each panel buttons were yellow and green two indicator: when the green light is on, indicating that can perform the function button; yellow light that is performing the function for the button.

6.automatic operation under the F1 or F2 can immediately terminate the operation; according to the F3 must complete the current action will stop running, that is, single step operation.

7.when the equipment appears abnormal warning lights flashing, troubleshooting, must be in the manual state, the reset operation, and then press the reset button.

8.units through the packaging line, no need to pack, cancel the bag, the program, at this time F7, F8 lights.

Three,matters needing attention

1.operation and maintenance personnel shall be trained and qualified.

2.daily inspection records, found that the problem report in time.

3.do not work at run time using the manual mode.

4.to prohibit the start of the device is not at the same time the safety protection function.

5.no artificial touch inductive switch or stroke switch.

6.do not shut down after the shutdown of the gas valve.

7.prohibit non designated personnel to modify the PLC program and other parameters.